When it comes to creating precise holes in various materials, the tools at your disposal can significantly affect the quality and efficiency of your work. Among the most common options are hole saws and hole cutters, both designed for similar purposes but differing in design, application, and functionality. Understanding the distinctions between these two tools can help users select the right one for their specific projects, ensuring optimal results.

At first glance, hole saws and hole cutters may appear similar, but their mechanisms and intended uses set them apart. A hole saw consists of a cylindrical metal body with serrated teeth along the edge. This design allows the tool to cut circular holes in materials like wood, plastic, and metal. Hole saws attach to a drill, and as the drill rotates, the teeth of the saw engage the material, gradually cutting out a circular section, known as a plug.

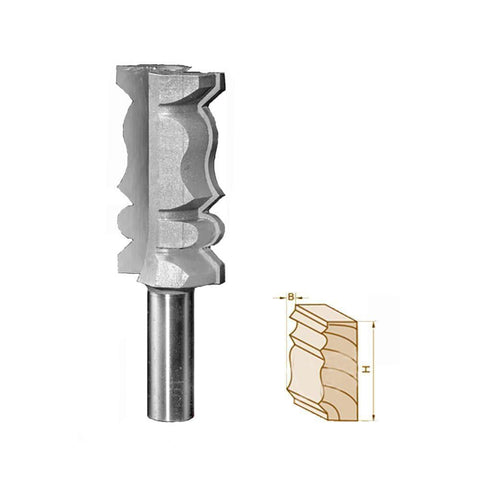

In contrast, hole cutters typically refer to tools that utilize a different approach to creating holes. Often seen in the context of more specialized equipment, hole cutters can come in various forms, including flat or cylindrical designs, but they often lack the serrated teeth found on hole saws. Instead, they may feature a sharp edge or blade that slices through the material, allowing for the creation of a hole. Some hole cutters are designed to be used with a specific type of drill or milling machine, making them suitable for more specialized applications.

The primary distinction between the two lies in the cutting action. Hole saws remove a core piece from the material, creating a hollow center, while hole cutters may cut through the entire thickness of the material, often leaving no core intact. This fundamental difference impacts the efficiency, precision, and application of each tool.

Hole saws are incredibly versatile and are used in a wide range of applications. They excel at creating holes for electrical outlets, plumbing fixtures, and various fittings. In woodworking, hole saws are ideal for drilling holes for dowels, hinges, and other hardware. Their ability to cut through a variety of materials makes them a go-to choice for both professionals and DIY enthusiasts. The serrated teeth of a hole saw allow for efficient cutting, and because they remove only the surrounding material, they tend to create a clean hole with minimal tear-out, particularly in softer woods and drywall.

On the other hand, hole cutters are often used in more specialized settings. For example, in metalworking, hole cutters may be employed to create precise openings in metal sheets or plates. They can be particularly effective when cutting through tough materials, as they can offer greater control and precision compared to traditional drill bits. Additionally, certain hole cutters are designed for specific tasks, such as creating holes in tiles or other hard surfaces, where the cutting action must be optimized for the material at hand.

Another notable difference is the variety of sizes and types available for each tool. Hole saws come in a broad range of diameters, allowing users to select the appropriate size for their specific needs. This versatility is one of the reasons hole saws are favored in many applications. Hole cutters, however, may not have the same range of sizes, and their effectiveness can be limited by the specific type of cutter being used.

In terms of cost, hole saws are typically more affordable and widely available in hardware stores and home improvement centers. They are considered a staple tool for many trades, making them a practical investment for anyone involved in construction, renovation, or woodworking. Hole cutters, while potentially more expensive, often require specialized equipment or setups, which can add to their overall cost.

When it comes to ease of use, hole saws are generally straightforward to operate, requiring minimal setup and compatible with most standard drills. Users can quickly switch between different sizes as needed, making them a convenient choice for various tasks. Hole cutters, however, may necessitate more specialized equipment or techniques, which can present a learning curve for those unfamiliar with their use.

Both hole saws and hole cutters have their place in the toolkit of tradespeople and DIY enthusiasts. The choice between them often depends on the specific project requirements and the materials being used. For tasks requiring clean, circular holes in wood, drywall, or soft metals, hole saws are usually the preferred option. Conversely, when precision cutting through thicker or tougher materials is necessary, particularly in industrial or metalworking settings, hole cutters may provide the advantage needed to achieve the desired results.

Ultimately, understanding the differences between hole saws and hole cutters allows users to make informed decisions about which tool to employ for a given task. By recognizing the strengths and limitations of each, one can optimize their workflow, enhance the quality of their work, and tackle a wide array of projects with confidence. Whether you're a seasoned professional or a weekend warrior, having the right tool for the job can make all the difference in achieving precision and efficiency in your cutting endeavors.